Requesting a Call:

8613506224031

Online Support

[email protected]

Visit Our Office

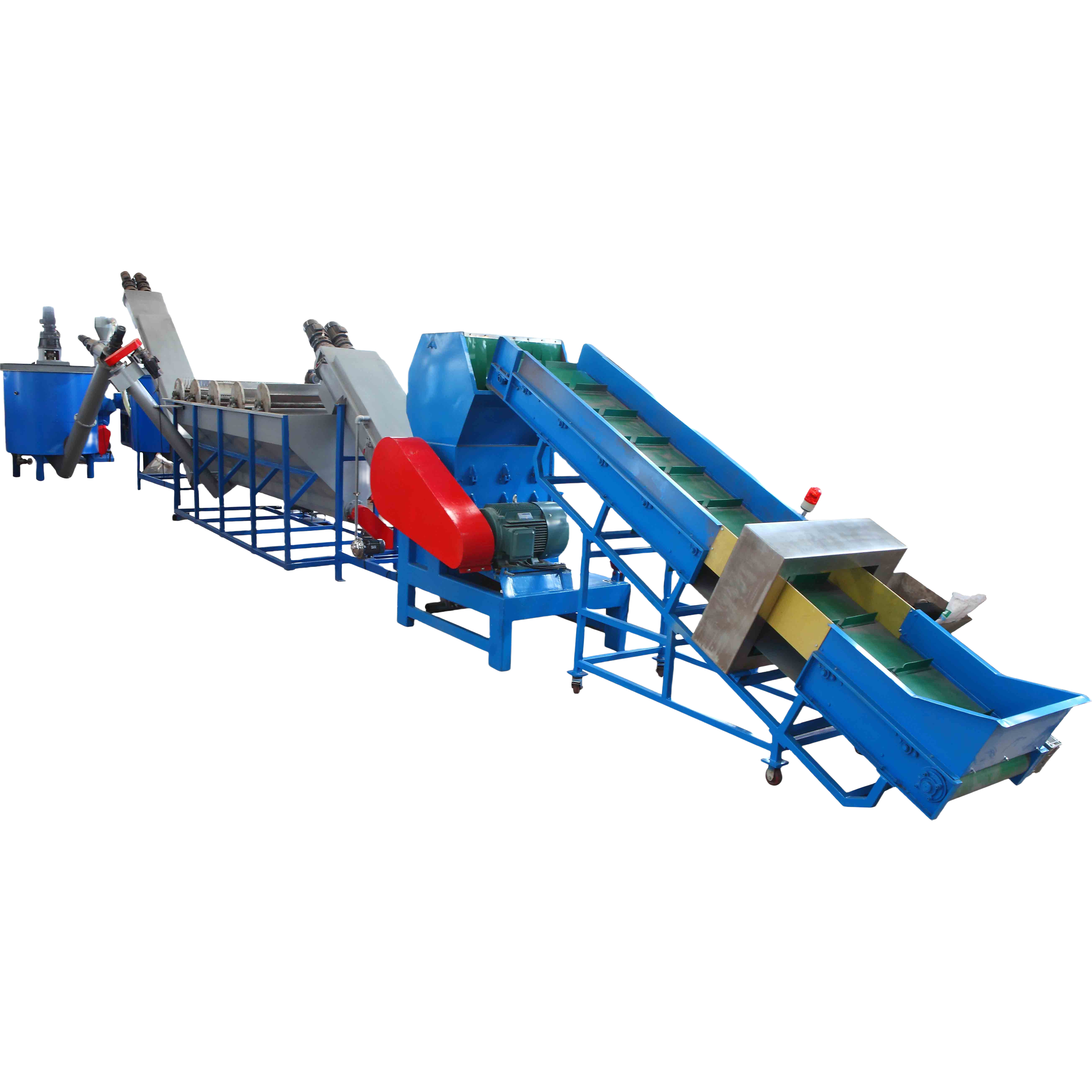

Suitable for cleaning PE/PP films, woven bags, jumbo bags, agricultural films, and other materials. It can thoroughly remove oil stains, mud, and other contaminants from the materials. After shredding, desanding, crushing, washing, and drying, the materials can be directly used for granulation.

The output ranges from 300kg/h to 1000kg/h and can be configured according to customer requirements.

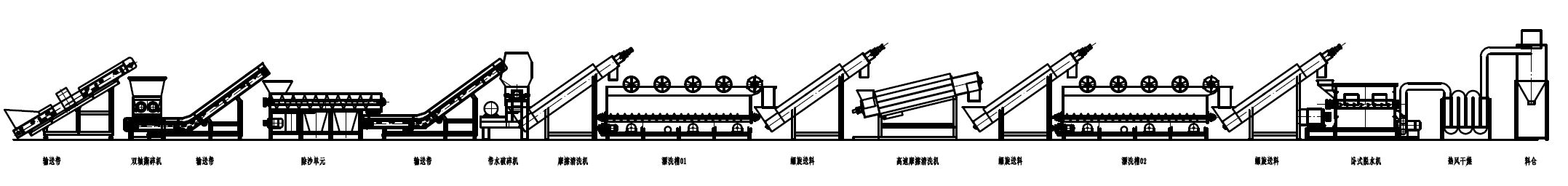

System Configuration

|

Item |

Description |

|

1 |

Belt Conveyer with Electric Magnetic |

|

2 |

Dual-shaft Shredder |

|

3 |

Belt Conveyer |

|

4 |

Desanding Unit |

|

5 |

Belt Conveyer |

|

6 |

Crusher (with Water) |

|

7 |

Friction Washing Unit |

|

8 |

Flotation (Rinsing) Washing Unit 01 |

|

9 |

Screw Conveyor |

|

10 |

High Speed Friction Cleaning Machine |

|

11 |

Screw Conveyor |

|

12 |

Flotation (Rinsing) Washing Unit 02 |

|

13 |

Screw Conveyor |

|

14 |

Centrifugal Dewatering Unit |

|

15 |

Electric Heating Unit |

|

16 |

Fan-Delivering Unit |

|

17 |

Spiral Pipe Delivering Unit (Drying) |

|

18 |

Electric Control Panel |

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy