Requesting a Call:

8613506224031

Online Support

[email protected]

Visit Our Office

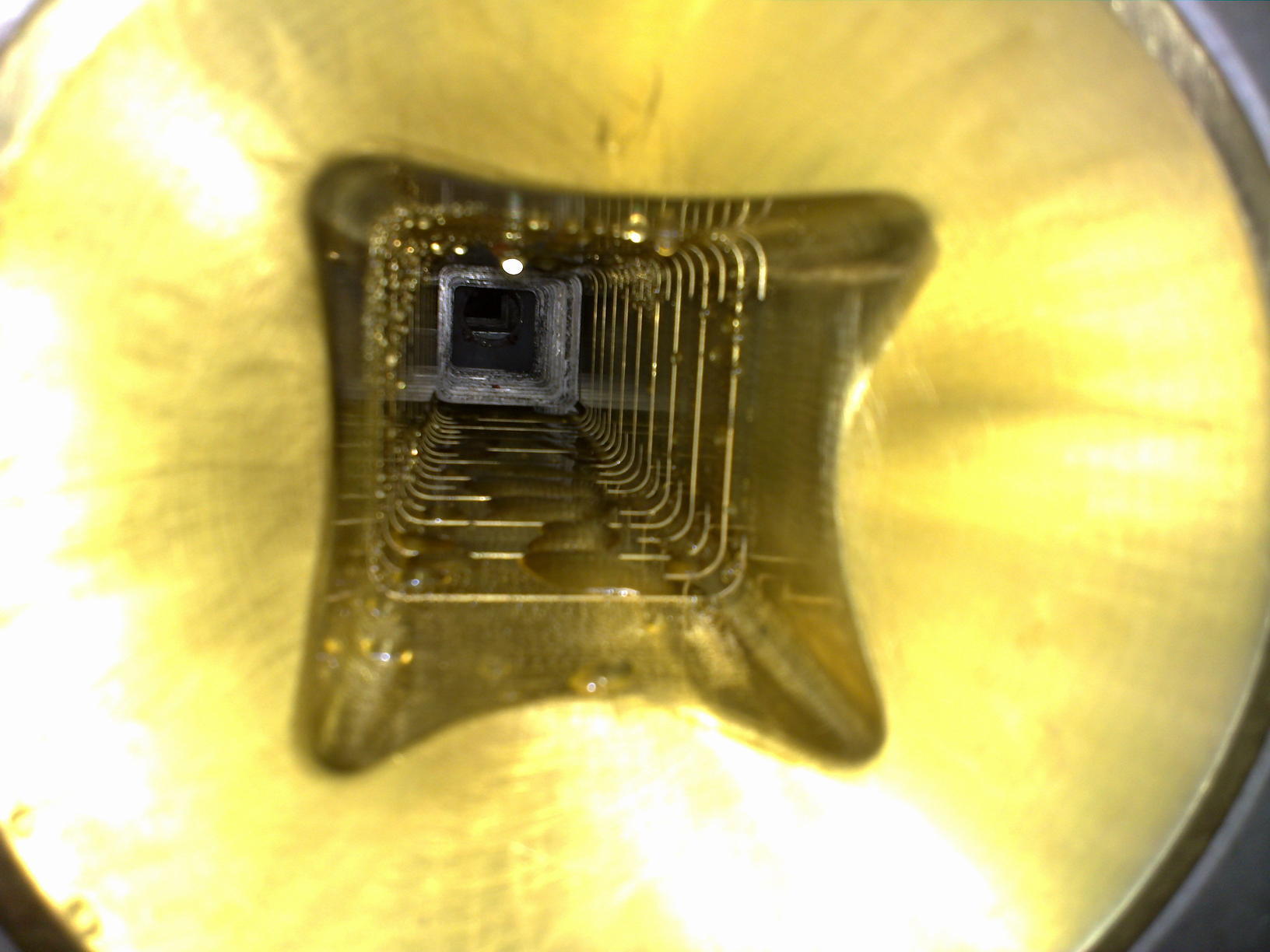

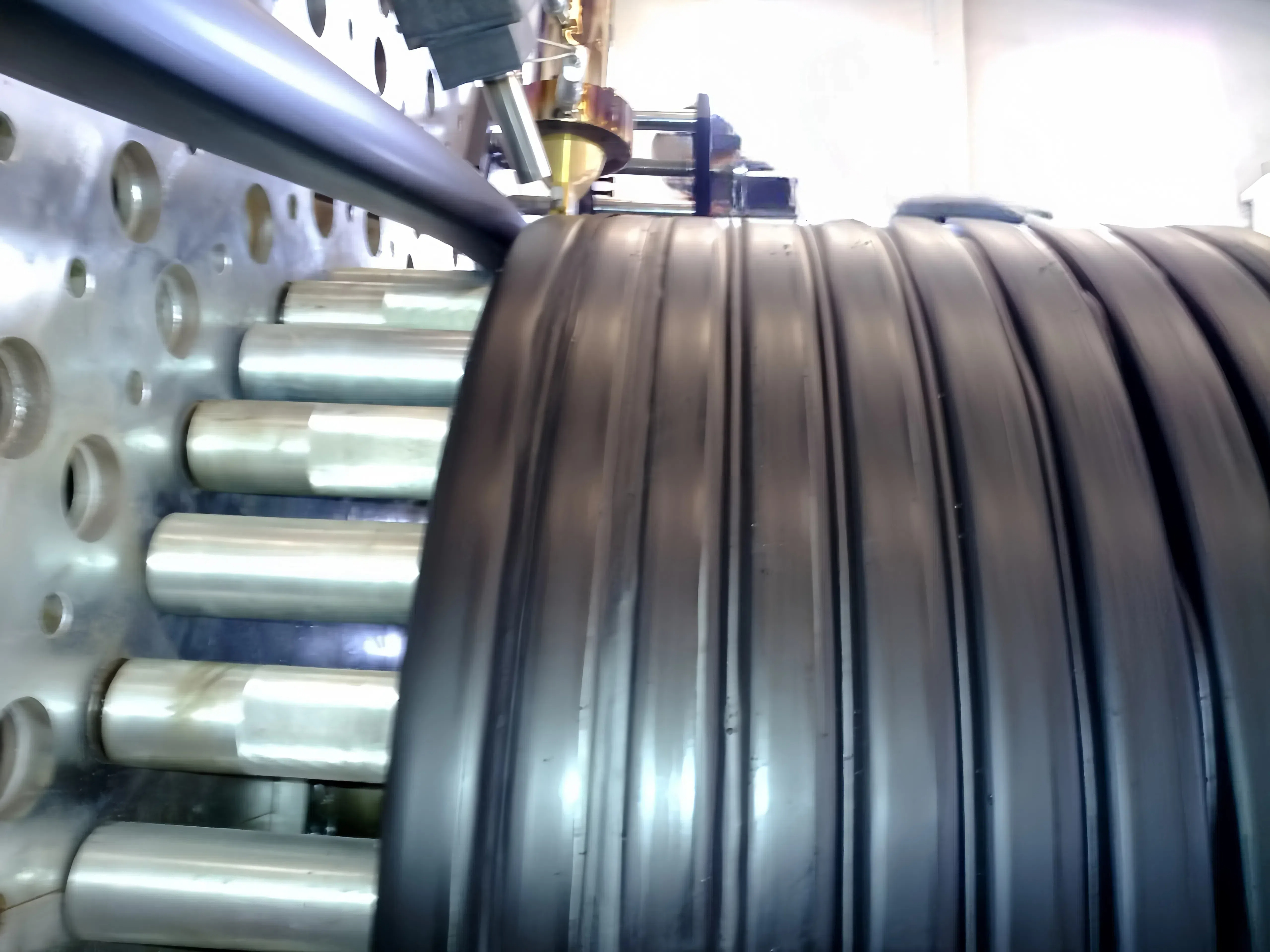

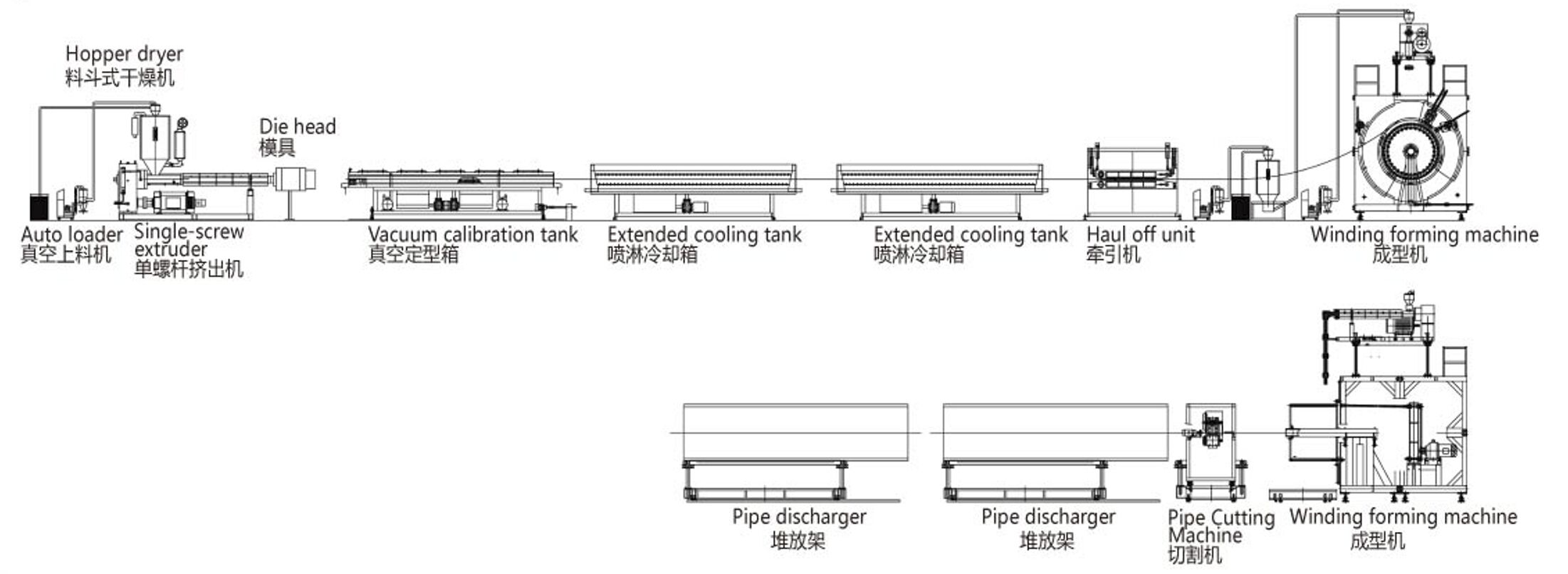

Based on fully assimilating and digesting European technology, our company has successfully developed a hollow-wall winding pipe production line. The pipes produced use high-density polyethylene (PE) as the main raw material. First, a rectangular pipe is extruded by the first extruder into the winding forming machine, while the second extruder sprays adhesive strips, which are then extruded and compounded. The inner and outer walls of these pipes are smooth and flat, with specifications ranging from Φ200 toΦ2800mm.

Dependingon different usage conditions, the ring stiffness is classified into four grades, with the highest reaching 16KN/m², and they can withstand acidic and alkaline liquids below 10%. These pipes possess advantages such as corrosion resistance, light weight, easy installation, high flow capacity, and long service life (50 years). They can replace high-energy-consuming materials (such as cement, cast iron, and ceramics) and are widely used in drainage and sewage systems in highways, municipal construction, residential communities, sports fields, squares, mines, agriculture, culverts, bridges, and other fields.

|

Model

|

Pipe Dia

|

Extruder

|

Total

Volume

|

Max.

Capacity

(kg/h)

|

Overall

Dimension(m)

|

|

|

Model

|

Power(kW)

|

|||||

|

CRG800

|

200-800

|

SJ75x33

SJ65x30

|

110

37

|

230

|

400

|

24x10x3

|

|

CRG1200

|

300-1200 |

SJ75x33

SJ65x30

|

110

37

|

260

|

550

|

30x13x5

|

|

CRG1600

|

800-1600

|

SJ90x33

SJ65x30

|

160

55

|

350

|

650

|

32x14x6

|

|

CRG2200

|

1200-2200

|

SJ120x33

SJ75x30

|

250

90

|

520

|

750

|

36x16x8

|

|

CRG3000

|

2200-3000

|

SJ120x33

SJ75x30

|

280

110

|

620

|

900

|

36x16x8

|

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy