recycled plastic injection molding

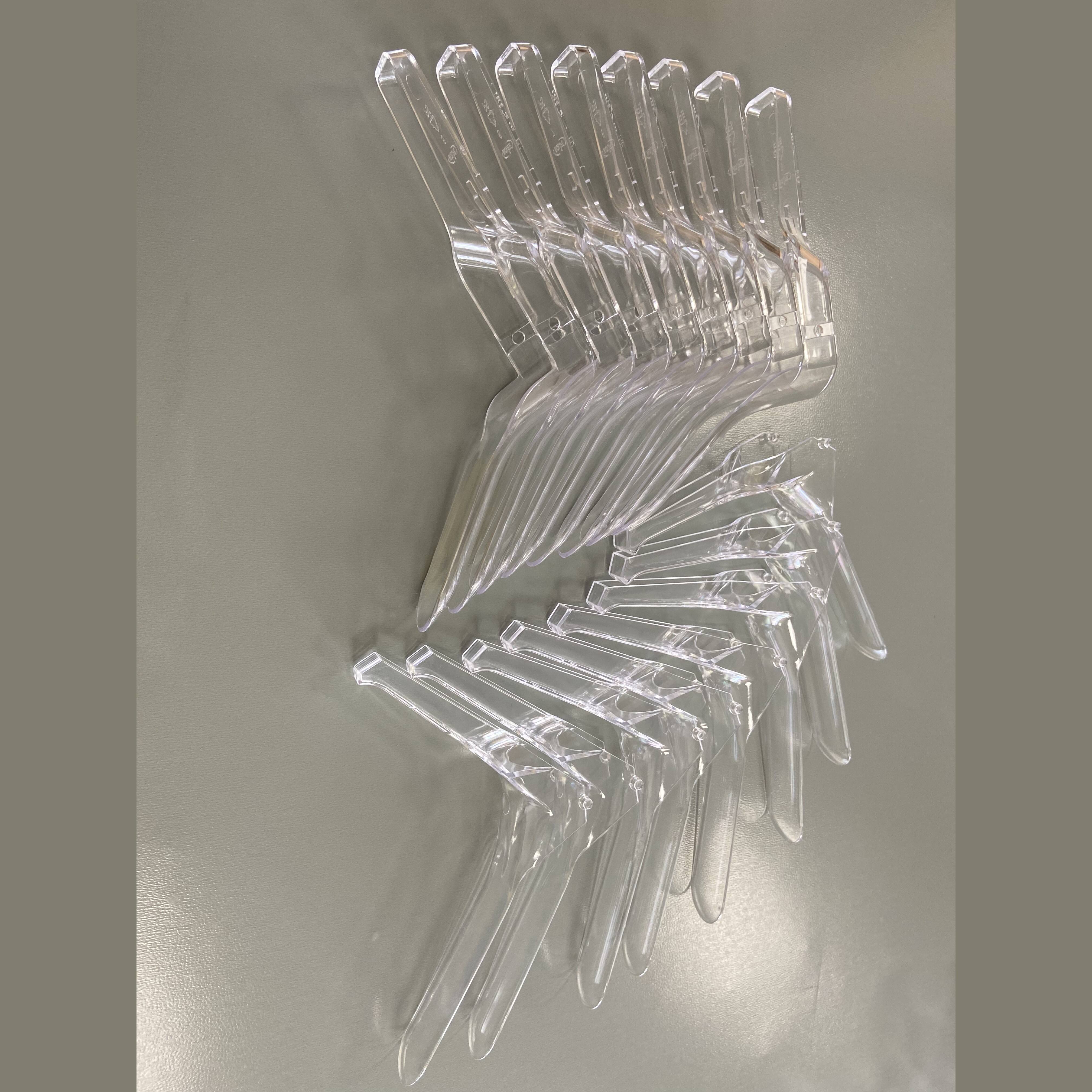

Recycled plastic injection molding represents a sustainable manufacturing process that transforms post-consumer and post-industrial plastic waste into valuable new products. This innovative technology combines traditional injection molding techniques with environmental responsibility by utilizing recycled plastic materials as the primary feedstock. The process begins with sorting and processing recycled plastics into uniform pellets, which are then heated until melted. The molten material is injected into precisely engineered molds under high pressure, creating complex shapes and products with consistent quality. This technology has revolutionized sustainable manufacturing by offering a practical solution to plastic waste while maintaining the high performance and versatility of traditional injection molding. The process accommodates various recycled plastics, including PET, HDPE, and PP, making it suitable for producing everything from consumer goods to industrial components. Advanced monitoring systems ensure quality control throughout the manufacturing cycle, while modern equipment enables precise temperature control and pressure management for optimal results.