Requesting a Call:

8613506224031

Online Support

[email protected]

Visit Our Office

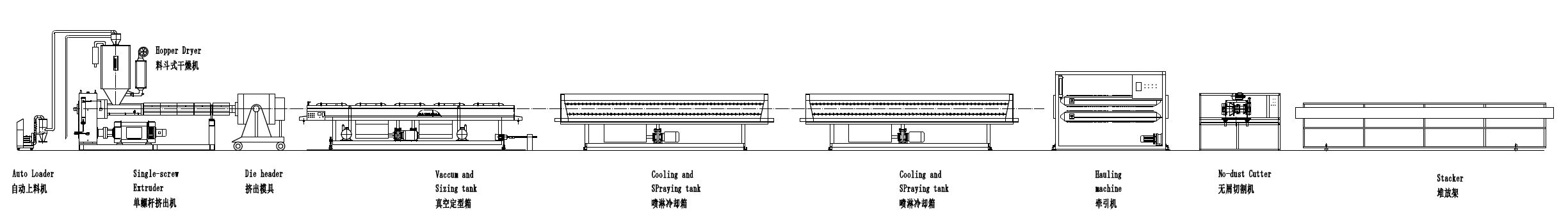

The screw of this extruder is equipped with barrier units and mixing units, and the barrel features a unique grooved structure to achieve excellent plasticizing and mixing effects. The special design of the basket mold used for large-diameter HDPE (PP, ABS) pipes reduces the melting temperature and main machine pressure, ensuring a good mixing effect and thus guaranteeing output.

The unique design of the cooling and sizing system employs water circulation cooling for HDPE (PP, ABS) materials, which is suitable for cooling these materials. The unique design improves the stability and roundness of the diameter, meeting the requirements for the production of thick-walled pipes.

The special design of the vacuum sizing box ensures the stability and roundness of the diameter, and the speed control system stabilizes the haul-off speed. The entire production line uses PLC control with an LCD control panel, making operation simple and convenient. It can be equipped with a color marker extruder to produce pipes with color marking lines.

Supporting Single-Screw Extruder: Suitable for PE resin extrusion with high output, with a maximum output of up to 1000 kg per hour.

Reasonable Design: The production line is designed with safety in mind and has obtained CE quality and safety certification.

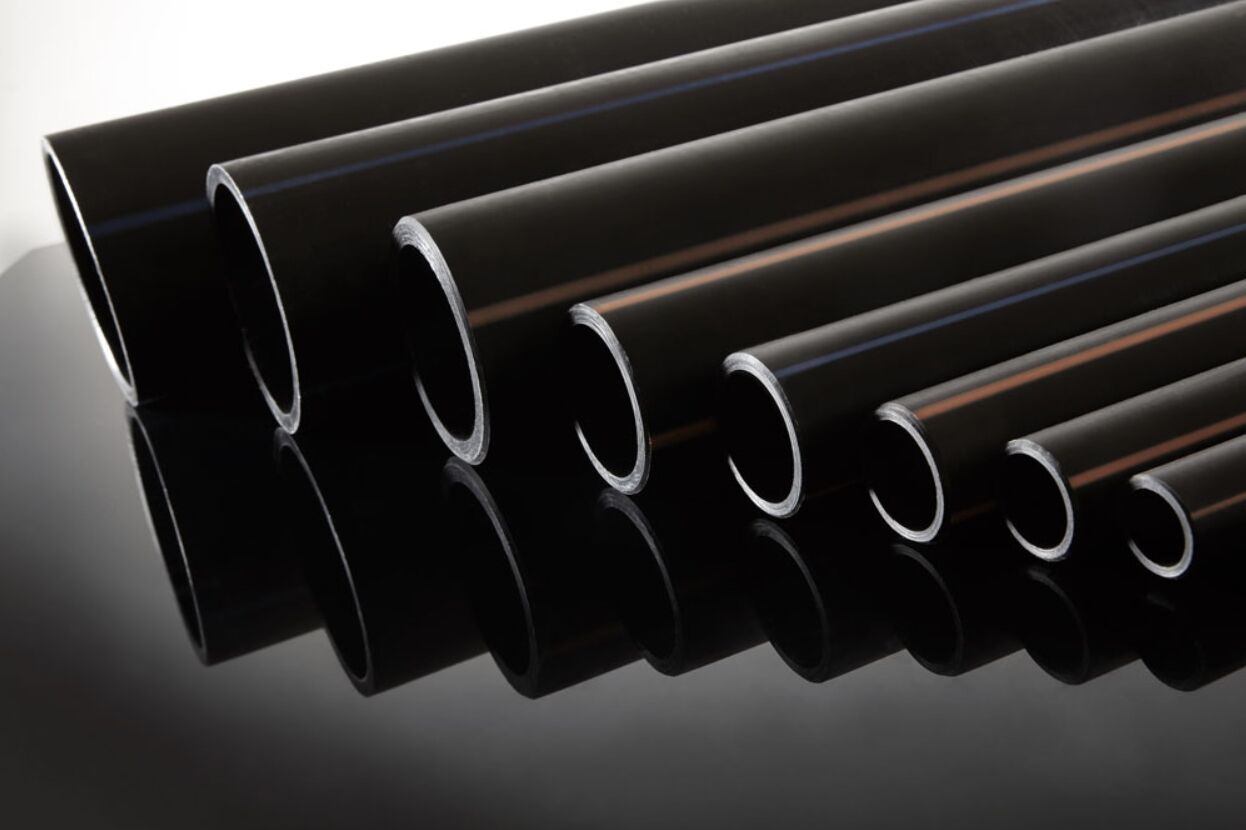

PE Pipe Diameter Range: 16 mm to 800 mm, which can be converted to imperial units to meet specific customer requirements.

Main technique parameters

|

Pipe range(mm) |

16-63 |

20-160 |

60-315 |

110-500 |

315-630 |

500-1200 |

|

Extruder |

SJ50 |

SJ60 |

SJ75 |

SJ90 |

SJ120 |

SJ150 |

|

L/D |

33-38/1 |

33-38/1 |

33-38/1 |

33-38/1 |

33-38/1 |

33-38/1 |

|

Extruder power(kW) |

30-55 |

55-90 |

75-160 |

90-220 |

160-315 |

160-355 |

|

Extrusion Capacity(kg/h) |

60-160 |

100-270 |

250-300 |

270-400 |

500-1000 |

500-1200 |

|

Max. Production Speed(m/min) |

10 |

6 |

4 |

3 |

0.7 |

0.3 |

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy