Requesting a Call:

8613506224031

Online Support

[email protected]

Visit Our Office

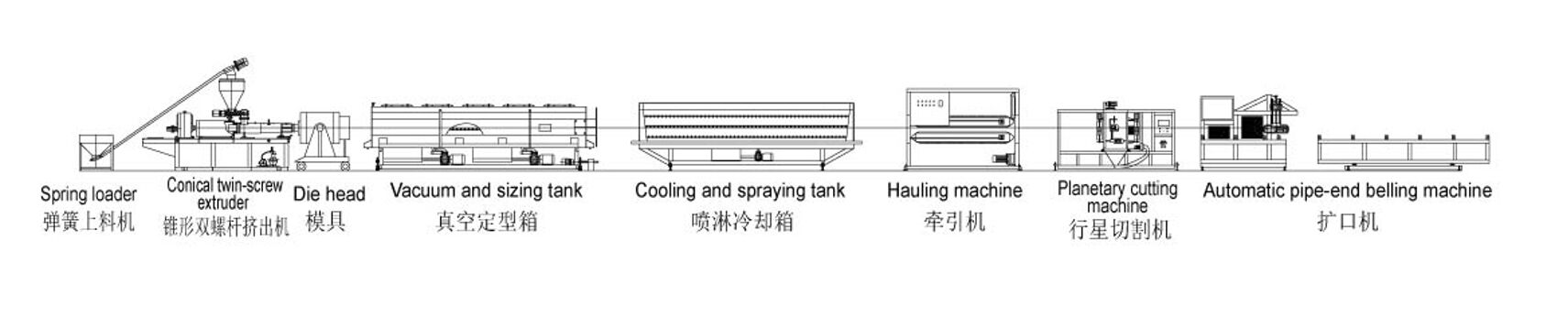

This production line is primarily used for the production of PVC water supply pipes, drainage pipes, electric conduit pipes, characterized by excellent quality and reasonable design.

Output: Conical twin-screw extruders are suitable for PVC powder production, with a maximum output of up to 1000 kg/h.

Diameter: Successfully designed to produce the world's largest conical twin -screw extrusion equipment, with a diameter of up to 710 mm.

Auxiliary equipment is custom-designed according to customer specifications, with a sleek and elegant appearance and easy operation of the automatic control system, ensuring stable production.

The ø20-ø630 series PVC pipe extrusion production line is mainly used for producing various diameters and wall thicknesses of plastic PVC pipes for agricultural drainage, building drainage, cable laying, etc. The unit consists of a conical twin -screw extruder, vacuum sizing machine, haul-off machine, cutter, and flipping rack. The extruder and haul-off machine adopt imported AC frequency conversion speed regulation devices, and high-quality products are used for the vacuum pump and traction motor. Traction methods include two- claw, three-claw, four-claw, six-claw, eight-claw, ten-claw, and twelve-claw. Cutting options include lift-cutting or planetary cutting, with length measurement and thickening devices available. The unit performs reliably with high production efficiency. Our company can configure dedicated devices according to customer requirements, enabling the production of spiral soundproof pipes and core layer foam pipe units.

Main technique parameters

|

Pipe Range(mm) |

20-100 |

110-315 |

200-500 |

315-630 |

|

Extruder |

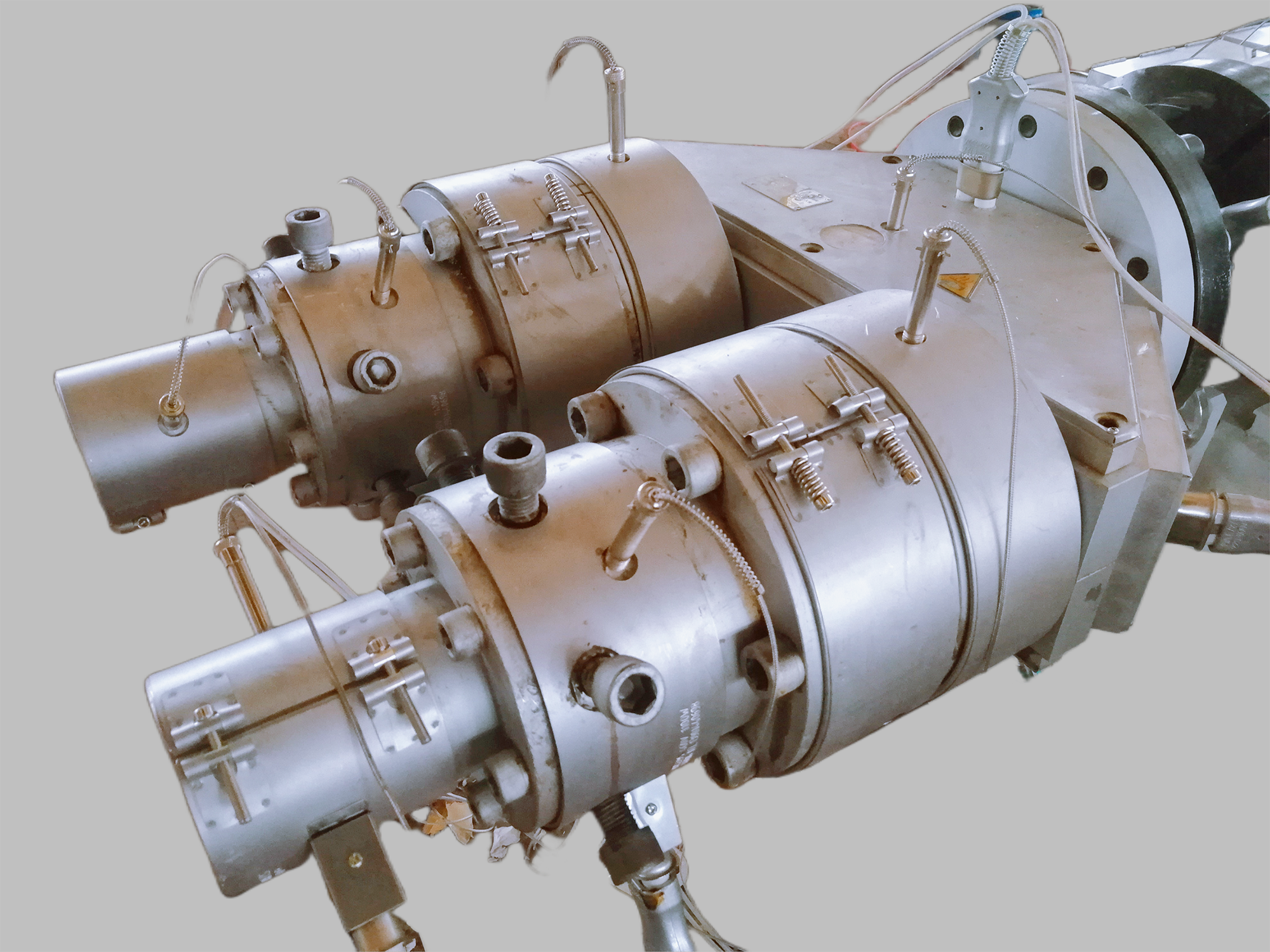

SJSZ51/105 |

SJSZ65/132 |

SJSZ80/156 |

SJSZ92/188 |

|

Extruder Power(kW) |

22 |

37 |

55 |

110 |

|

Extrusion Capacity(kg/h) |

120 |

250 |

450 |

800 |

|

Max. Production Speed(m/min) |

10 |

10 |

3 |

1.2 |

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy