Requesting a Call:

8613506224031

Online Support

[email protected]

Visit Our Office

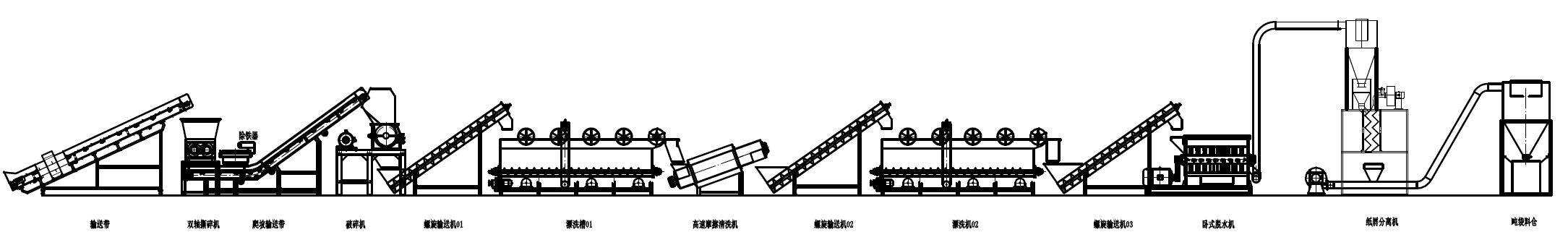

This production line is mainly used for processing hard plastics such as PP, PE, PS, and PVC. Through the processes of shredding, crushing, washing, dewatering, drying, and sorting,clean and sorted plastic flakes of PP, PE, and other types are obtained.

System Configuration

|

Item |

Description |

|

1 |

Belt Conveyer with Electric Magnetic |

|

2 |

Dual-shaft Shredder |

|

3 |

Iron Remover |

|

4 |

Belt Conveyer |

|

5 |

Crusher (with Water) |

|

6 |

Screw conveyor |

|

7 |

Flotation (Rinsing) Washing Unit 01 |

|

8 |

High Speed Friction Cleaning Machine |

|

9 |

Screw conveyor |

|

10 |

Flotation (Rinsing) Washing Unit 02 |

|

11 |

Screw conveyor |

|

12 |

Centrifugal Dewatering Unit |

|

13 |

Small Paper and Label Separator |

|

14 |

Fan-Delivering Unit |

|

15 |

Silo |

|

16 |

Electric Control Panel |

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy