Запрос на звонок:

8613506224031

Онлайн поддержка

sales@bxkm.com

Посетите наши офисы

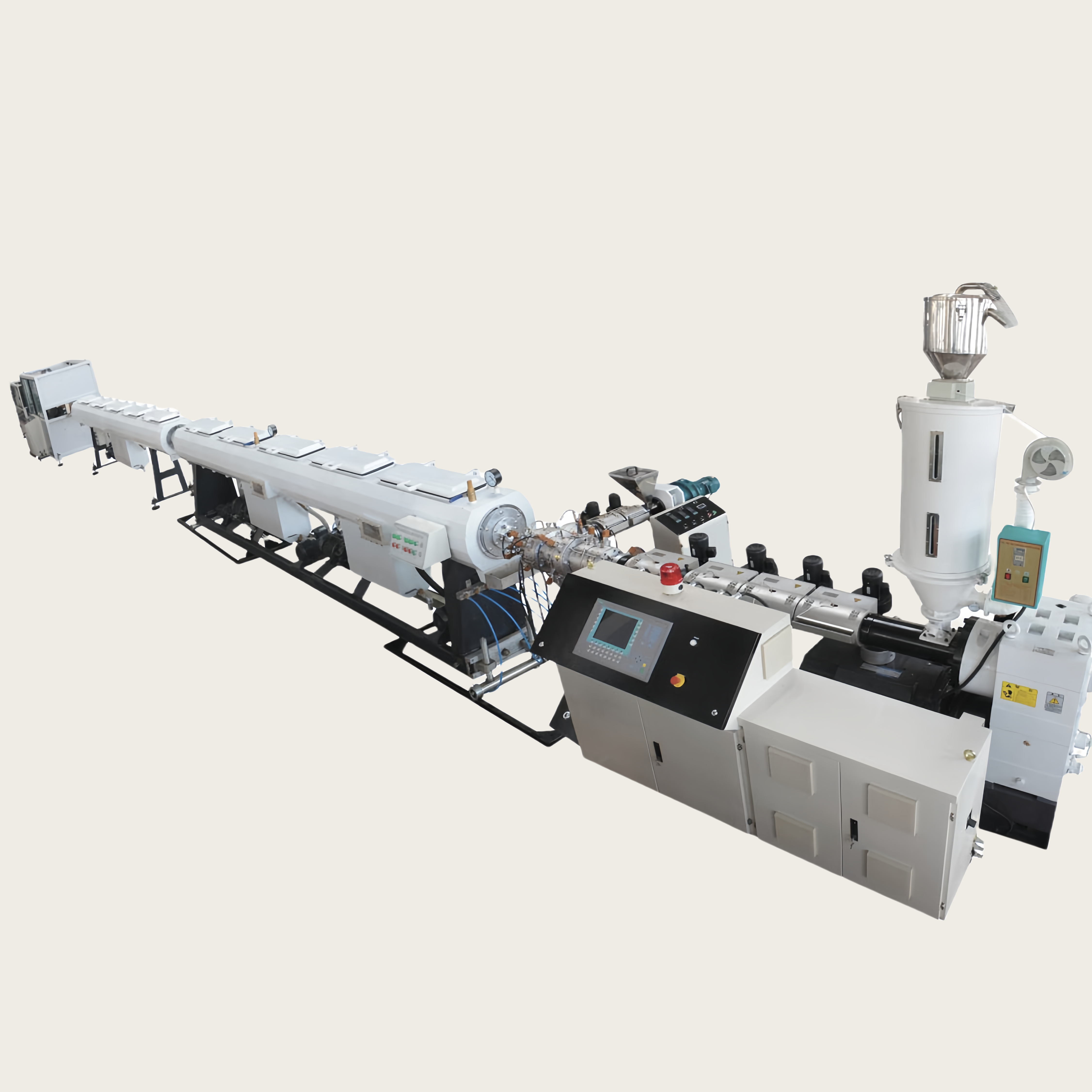

«Наша линия производства экструзии пластиковых труб обеспечивает постоянную и эффективную производительность при выпуске различных пластиковых труб для разных отраслей. Снабженная передовой технологией экструзии, эта линия способна поддерживать непрерывный и высококачественный выпуск продукции, экономя энергию. Она создана с такой точностью, что может обрабатывать различные пластические материалы, включая ПВХ, ПЭ и, безусловно, ПП, для таких областей применения, как строительство, сельское хозяйство и водоснабжение.

Благодаря современным системам автоматизации и управления, включенным в производственный процесс, достигаются короткие циклы без потери точности. Гибкость опций экструдера позволяет изменять диаметр и толщину труб в соответствии с потребностями клиентов. Разработанная для эффективной и беспроблемной эксплуатации с минимальным обслуживанием, наша линия экструзии пластиковых труб является экономически эффективным и надежным оборудованием. Подходит для массового производства, эта система является важным инструментом для предприятий, планирующих расширение производства пластиковых труб.

Производство экструзии пластиковых труб является современным процессом формирования, актуальным для требований отраслей, нуждающихся в высококачественных долговечных трубах. Этот метод состоит в нагревании различных видов сырья из пластика до тех пор, пока оно не расплавится в жидкий пластик, после чего его выдавливают через матрицу для формирования труб желаемой длины, размера и толщины. Особенность данного процесса заключается в том, что он непрерывный, что способствует массовому производству необходимых изделий за короткий период времени. Можно использовать различные виды пластикового сырья на производстве, так как система экструзии пластиковых труб позволяет использовать экструдеры, что дает безграничные возможности в производстве. Изменяя параметры процесса экструзии, можно создавать трубы с определенной прочностью, пластичностью и другими характеристиками, соответствующими допустимым нормам промышленных стандартов. Процесс экструзии пластиковых труб находит применение в различных отраслях, таких как строительство, водоочистка и производство фитингов.

Производство экструзии пластиковых труб имеет своей одной из главных выгод высокую эффективность. Процесс является непрерывным, поэтому массовое производство возможно с соблюдением установленных стандартов. Также есть возможность производить трубы разных диаметров в различных дизайнах, что дает промышленным предприятиям гибкость в их процессах. Кроме того, метод экструзии эффективен в снижении отходов, так как количество используемого пластика на этапе производства ограничено, и используется только необходимое количество. Помимо этого, потребление энергии во время процесса экструзии пластиковых труб также очень низкое, что приводит к общему снижению стоимости производства, делая этот процесс отличным для предприятий, которые хотят увеличить свой объем выпуска.

Среди этапов процесса производства пластиковых труб, согласованность конечного продукта является одним из самых важных факторов. Метод экструзии позволяет управлять несколькими параметрами, такими как температура, давление, скорость и т.д., которые влияют на качество производимых труб. Кроме того, производители используют машины для контроля качества экструзии, чтобы производить трубы, которые не потеряют свою форму, прочность и долговечность в процессе производства. Это требует особенно высокого уровня обеспечения качества при производстве всех пластиковых трубопроводных систем, которые должны прослужить долго под высоким давлением и при интенсивной эксплуатации. Эти сложные требования могут быть удовлетворены с помощью экструзии пластиковых труб.

Устойчивое развитие становится все более важной проблемой во многих отраслях, и производство пластиковых труб методом экструзии может способствовать более экологичным практикам. Сам процесс экструзии создает минимальное количество отходов, так как пластиковые материалы используются эффективно, что снижает количество избыточного материала. Помимо этого, пластиковые трубы, произведенные методом экструзии, часто являются перерабатываемыми, что позволяет отраслям сократить их экологический след. Более того, достижения в технологии экструзии пластиков сделали возможным использование вторсырья в производственном процессе без ущерба для качества конечного продукта. Внедряя устойчивые практики в производстве пластиковых труб методом экструзии, отрасли могут достичь как эффективности, так и экологической ответственности в своей деятельности.

Компания Zhangjiagang Baixiong Klimens Machinery Co., Ltd. основана в 1998 году и является национальным высокотехнологичным предприятием, специализирующимся на технологии переработки, смешивания и экструзии пластика. Основные продукты компании: За годы практики мы накопили многочисленные эффективные опыты производства и можем настроить оборудование в соответствии с потребностями клиентов, предоставляя эффективные решения для наших клиентов. Компания обладает независимыми правами на интеллектуальную собственность и высокотехнологичными возможностями разработки продукции, имеет множество патентов на изобретения и полезные модели. Качество продукции контролируется в соответствии с системой менеджмента качества ISO9001-2015 и европейской сертификацией CE. Предприятие получило многочисленные национальные и провинциальные сертификаты и создало сотрудничество с университетами.

30

Sep

30

Sep

30

Sep

Экструзия пластиковых труб включает в себя плавление сырья из пластических материалов и проталкивание его через формующую матрицу для создания труб. После этого трубы охлаждаются и режутся на нужные длины. Этот процесс обеспечивает непрерывное производство труб одинакового размера, которые используются в различных приложениях, таких как сантехника, орошение и строительство.

Распространенные материалы, используемые в экструзии пластиковых труб, включают ПВХ (поливинилхлорид), ПНД (полиэтилен высокой плотности) и ППР (полипропилен). Эти материалы выбираются за их прочность, гибкость и устойчивость к химическим веществам, что делает их идеальными для различных промышленных и бытовых применений.

Экструзия пластиковых труб предлагает преимущества, такие как экономичность, высокая скорость производства и материалоемкость. Процесс создает прочные, легкие трубы, устойчивые к коррозии и химическому воздействию. Он также энергоэффективен, снижает отходы и позволяет производителям эффективно удовлетворять высокий спрос.

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Политика конфиденциальности