Requesting a Call:

8613506224031

Online Support

[email protected]

Visit Our Office

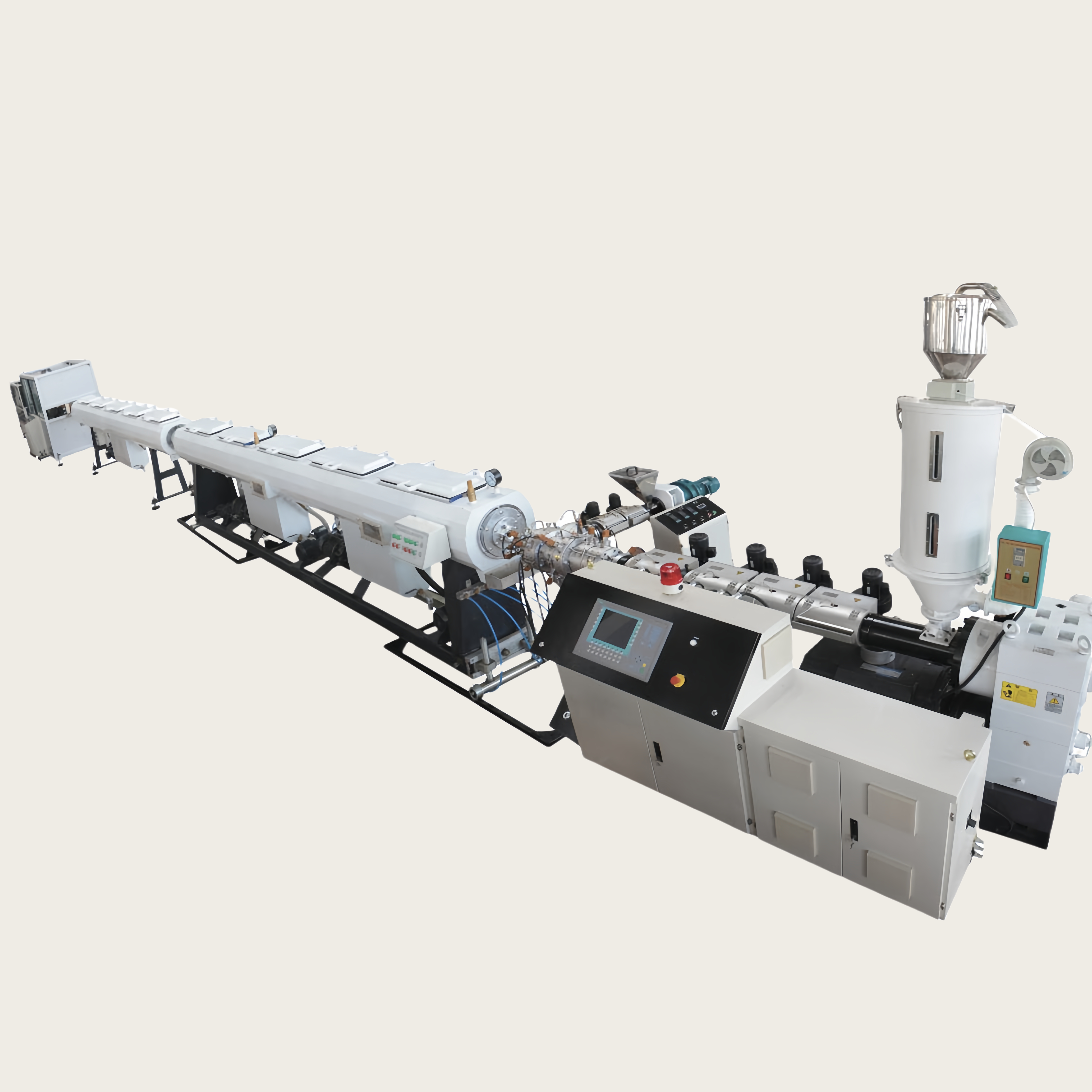

'Our plastic pipe extrusion production line provides a consistent and effective efficiency while producing a variety of plastic pipes, for different industries. Powered with advanced extrusion technology, this production line is able to maintain a continuous and high quality output, while conserving energy. It is built with such accuracy that it can process a variety of plastic materials including PVC, PE, and clearly PP as such application domains include construction, agriculture, and water supply.

Due to modern automation and control systems included in the production process, fast cycle times are achieved without loss of accuracy. The versatility of the options of the extruder enables change of pipe diameter and thickness to suit customer needs. Designed for efficient and headache-free operation and low maintenance, our plastic pipe extrusion production line is cost-effective production and durable machinery. Suitable for bulk fabrication, this system is an important tool for enterprises intending to expand into increased plastic pipe production.'

Sustainability is a growing concern in many industries and plastic pipe extrusion production can contribute to more environmentally friendly practices The extrusion process itself generates minimal waste as the plastic material is used efficiently reducing the amount of excess material Additionally plastic pipes produced through extrusion are often recyclable allowing industries to reduce their environmental footprint Furthermore advancements in plastic extrusion technology have made it possible to incorporate recycled materials into the production process without compromising the quality of the final product By adopting sustainable practices in plastic pipe extrusion industries can achieve both efficiency and environmental responsibility in their operations

The production of plastic pipe extrusion is a modern factor formation process that is relevant for the requirements of industries needing high-quality long-lasting pipes. This method consists of heating various raw plastics until they melt into molten plastic and extruding it using a die to form pipes of desired length, size, and thickness. The nature of this process is such that it is non-stop thereby encouraging mass production of the required goods in a short time period. Variety of plastics raw material can be used in the workshop as the plastic pipe extrusion system enables one to use extrudes so giving unbounded ability in production. By varying the parameters of the extrusion process, the strength, ductility and other characteristics of the pipe products are made within the allowable range of industrial standards. The plastic pipe extrusion process finds application in diverse industries like construction, water treatment and fittings manufacturing among others.

Among the stages of the manufacturing process of plastic pipes, the consistency of the final product is one of the most important factors. The extrusion method as it enables the management of several parameters, such as temperature, pressure, speed, etc., which influence the quality of pipes produced. Additionally the producers employ the use of quality control extrusion machines to produce pipes that will not lose their shapes, strength and durability during the production process. This requires especially high quality assurance in the manufacture of all plastic plumbing pipes which are expected to last for a long time under high pressure and in heavy use. These demanding applications can be met by plastic pipe extrusion.

Plastic pipe extrusion production has its efficiency as one of its main benefits. The process is continuous and therefore bulk production is feasible with set standards being adhered to. There is also the ability to manufacture pipes of different diameters in a variety of designs which gives industries the flexibility in their processes. Besides, the extrusion method is efficient in cutting down wastages since the amount of plastic that is to be used at the stage of manufacturing is limited so that only the required amount is used. Besides, the consumption of energy during the plastic pipe extrusion process is also very low which leads to the overall reduction of production cost which makes it an excellent process for industries that want to increase their output.

Zhangjiagang Baixiong Klimens Machinery Co., Ltd. established in 1998, is a national high-tech enterprise specializing in plastic recycling, mixing, and extrusion technology. The company's main products include . Through years of practice, we have summarized numerous effective manufacturing experiences and can customize equipment according to customer needs, providing efficient solutions for our clients. The company possesses independent intellectual property rights and high-tech product development capabilities, holding multiple invention and utility model patents. Product quality is controlled under the ISO9001-2015 quality management system and CE European certification. The enterprise has received numerous national and provincial certifications and has established graduate cooperation stations with universities.

30

Sep

30

Sep

30

Sep

Plastic pipe extrusion involves melting raw plastic materials and forcing them through a shaped die to form pipes. The pipes are then cooled and cut to the required lengths. This process ensures continuous production of uniform pipes used in various applications such as plumbing, irrigation, and construction.

Common materials used in plastic pipe extrusion include PVC (polyvinyl chloride), HDPE (high-density polyethylene), and PPR (polypropylene). These materials are chosen for their durability, flexibility, and resistance to chemicals, making them ideal for various industrial and domestic applications.

Plastic pipe extrusion offers benefits such as cost-effectiveness, high production speed, and material versatility. The process produces durable, lightweight pipes that resist corrosion and chemical damage. It is also energy-efficient, reducing waste and allowing manufacturers to meet high demand efficiently.

Copyright © 2024 by Zhangjiagang Baixiong Klimens Machinery Co., Ltd. | Privacy policy